A8 D2 Oil Cooler Leaking - Need Cost Estimates for Whats Fair

#21

AudiWorld Member

Thread Starter

Join Date: May 2013

Location: san diego, ca

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

well, they arent wrong. bare aluminum will corrode like crazy in the engine coolant. i guess if you flush your coolant often it shouldnt be an issue but aluminum will corroded much much faster in coolant than stainless will. the claim is certainly justified.

but i agree, anything is better than plastic. dog doo would be better than what Audi used...and they should be ashamed of letting the accountants get the best of their engineering.

but i agree, anything is better than plastic. dog doo would be better than what Audi used...and they should be ashamed of letting the accountants get the best of their engineering.

#22

AudiWorld Super User

well, they arent wrong. bare aluminum will corrode like crazy in the engine coolant. i guess if you flush your coolant often it shouldnt be an issue but aluminum will corroded much much faster in coolant than stainless will. the claim is certainly justified.

but i agree, anything is better than plastic. dog doo would be better than what Audi used...and they should be ashamed of letting the accountants get the best of their engineering.

but i agree, anything is better than plastic. dog doo would be better than what Audi used...and they should be ashamed of letting the accountants get the best of their engineering.

And AGAIN >>> stainless against aluminum (alusil) can cause a chemical reaction called CONTACT CORROSION. Bentley publishing did not just make this up...ALL their info comes directly from Audi engineers, all of whom know infinitely more than you on this and most subjects.

Give it a rest already...reality is reality...it's OK to be wrong occasionally...I was once.

#23

AudiWorld Senior Member

Join Date: Aug 2006

Location: Melbourne, Victoria, Australia

Posts: 885

Likes: 0

Received 0 Likes

on

0 Posts

I don't normally do this quote on quote stuff, but I do need to defend my argument here...

Most of these bolts will bolt into dry holes and they're necessary as aluminium bolts will simply not be strong enough for the job (or for the mechanics which handle them in workshops, or for cost).

Corrosion remains dormant whilst air and moisture is kept away. Tightly torqued down bolts into dry aluminium holes will basically not corrode, plus most of the bolts are zinc plated (which is a sacrificial metal, even to aluminium - it will corrode first) or otherwise coated and they are exposed to oil over time which is a natural corrosion inhibitor, mainly because it sticks and locks out moisture.

The O-rings are irrelevant. You've put the stainless steel into an electrolytic environment. The electrolyte (coolant) acts as the conductor. The o-rings actually aid the electrolyte in its job by separating the metals (the electrodes in a battery don't touch). The only thing limiting any corrosion is the corrosion inhibitors in the coolant. But these are sacrificial, and do wear out of the coolant.

In fact, on some investigation into the nobility of metals, stainless steel (due to its chromium content) is hugely more corrosive of aluminium than basic steel is (http://en.wikipedia.org/wiki/Galvanic_series (in this chart, the stainless you're using would be passive, and 303 would be higher in the chart than the 304 as listed)).

The arguement could be said that the water pump impeller is also steel. Fair enough. But it is far closer to aluminium in the galvanic chart then stainless steel is and it also gets replaced every timing belt job and most people would replace the coolant at the same time.

I'm not saying this corrosion is necessarily quick, or that the coolant won't do it's job, but I wouldn't use anything but an aluminium part submerged in coolant.

As Sam said, G12 was specifically developped for alloy systems, and specifically prevents alloy corrosion.

It was also designed to prevent Aluminium corrosion in heads and radiators where a steel block is employed (such as the Audi 1990's V6 engines), so there is some value to it in that cell.

Bare in mind that the materials used in the Audi A8 series bodies and engines share more in common with material technologies of aircraft than those of old American V8's and steel bodied cars.

...I have studied engineering materials in Aerospace Engineering. It was a long time ago, but I'd like to think a small amount has stuck!

Corrosion remains dormant whilst air and moisture is kept away. Tightly torqued down bolts into dry aluminium holes will basically not corrode, plus most of the bolts are zinc plated (which is a sacrificial metal, even to aluminium - it will corrode first) or otherwise coated and they are exposed to oil over time which is a natural corrosion inhibitor, mainly because it sticks and locks out moisture.

also keep in mind there are also 4 little things called o-rings on these parts, which are actually what makes contact between the cast aluminum engine block and the oil pipe, so the dissimliar metals argument is moot, there isnt actually any stainless to aluminum touching.

In fact, on some investigation into the nobility of metals, stainless steel (due to its chromium content) is hugely more corrosive of aluminium than basic steel is (http://en.wikipedia.org/wiki/Galvanic_series (in this chart, the stainless you're using would be passive, and 303 would be higher in the chart than the 304 as listed)).

The arguement could be said that the water pump impeller is also steel. Fair enough. But it is far closer to aluminium in the galvanic chart then stainless steel is and it also gets replaced every timing belt job and most people would replace the coolant at the same time.

I'm not saying this corrosion is necessarily quick, or that the coolant won't do it's job, but I wouldn't use anything but an aluminium part submerged in coolant.

It was also designed to prevent Aluminium corrosion in heads and radiators where a steel block is employed (such as the Audi 1990's V6 engines), so there is some value to it in that cell.

Bare in mind that the materials used in the Audi A8 series bodies and engines share more in common with material technologies of aircraft than those of old American V8's and steel bodied cars.

...I have studied engineering materials in Aerospace Engineering. It was a long time ago, but I'd like to think a small amount has stuck!

Last edited by twentysevenlitres; 07-19-2014 at 12:15 AM.

#25

AudiWorld Member

Thread Starter

Join Date: May 2013

Location: san diego, ca

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

I emailed the vendor and directed them to this thread and asked for their take on it, here is the response from gruven :

"We developed the stainless version of this part specifically for our driving school/track day customers with the 4.2 V8 in response to the all too frequent failures of the plastic pipe. We have been producing similar coolant system parts from 303 stainless for over 10 years and have seen the engines during overhaul / complete teardown after 5+ years in the worst possible environments (neglect, track abuse, more neglect, ect...) We have NEVER seen any galvanic corrosion on the stainless (or mating aluminum) parts whatsoever. In theory there may be an argument for galvanic corrosion, but in reality there has been no evidence to support these claims. We make these parts from stainless mainly for the hardness/increased strength over the aluminum (and at the request to our track day customers). That said, if you would rather us make from 6061-T6511, WE WOULD LOVE TO !! The price would come down as that is a MUCH softer material, and much easier to machine. Its a real pain to machine the stainless but we always go to extra efforts to please our customers. Please let us know if any other questions, we are always open for suggestions."

#26

AudiWorld Super User

An unsubstantiated claim (like that aluminum corroding problem that doesn't exist in this case) from an advertiser depending on selling a product because of it, is not proof or even a valid argument.

EMPI's aftermarket $79 axle shafts/CV's, arguably the WORST and shortest lived axles in the industry come with a claim of being "OEM Quality" and a LIFETIME Warranty attached...that claim and warranty are NOT a certification or proof of quality...it's just a simple business/advertising decision that doesn't quite break any government regulations.

Gruven are the same guys who asked (and received) my permission to use my tutorial on their site, then added all kinds of messages to it that had nothing to do with my content or any message/opinion of mine...I assumed they wanted it just to help customers install the product they sell, not to turn it into an endorsement of their product and recommending tossing out perfectly good working OEM arms...many plastic arms NEVER break, especially if the system is maintained, as I recommend there.

...and, in your message from Gruven, they added one more bulls##t argument to the mix >>>

"We make these parts from stainless mainly for the hardness/increased strength over the aluminum"

As you may have read in my post #8 here, the physical "strength" of the plastic tube has NOTHING to do with it's failure...it is plenty "strong" enough, since there is ZERO physical stress on it...Unlike plastic, aluminum will not turn to brown sugar when it remains in contact with a hot engine block for years...heat resistance/dissipation is the cure, NOT steel-strength.

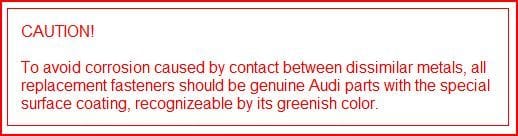

And speaking of "printed claims":

Below is the 115th warning posted in the Bentley D2 manual (not out to sell ANYTHING...already sold before viewing).

This particular one in a section discussing attaching parts to the engine block >>

The point:

Gruven lies, just like Raxles (another seller of a probable quality product?) who feels the need to be deceptive and outright lie on their website.

Again, there is not ONE practical reason, for this application, to use stainless over aluminum (unless that side of your car is a few grams shy of perfect weight balance...and no good reason for Gruven to lie about it, leave out "inconvenient" info and just make up crap, except to make a sale.

I'd rather have an aluminum D2 than a stainless DeLorean

Cheers

Last edited by silverd2; 12-31-2014 at 05:21 AM.

#27

AudiWorld Junior Member

Silverd, twentysevenliters, S8silver, and others

Great posts here, this oil coolant pipe issue is a big deal, and it is great to see so much expert advice and suggestions here - maybe it should be in the FAQ

Audinut87 - i suggest you take a good read of the comments, and maybe think twice about listening to your mechanic - yes, he may be a good wrench-turner, but is he a materials engineer? The forum comments here are well-thought and dead on.

The aluminium vs Stainless is discussion really turns on basic chemistry and physics here, no amount of marketing by gruven or any vendor can change the laws of physics... although they will try to convince you otherwise, that's why a reality-check such as is provided on these forums is so helpful.

The whole stress argument is silly at best, in a material critical environments such as in the aluminum engine, use the best material for the job, not just the strongest or lightest, or most expensive, or sexiest.

303 Stainless is a very bad idea, and most probably will cause problems, plastic was probably used as it was cheaper, obviously could not cause galvanic corrosion, and it is a very low stress (re: strength) environment, so Audi saved a few bucks, but caused problems - however, replacing it with stainless will cause additional problems. This Stainless replacement product really should not be used in the aluminum block, and any smart or well-read mechanic would appreciate that.

Also, no reason to insult the ebay seller, he provides a great product at a great price.

I am happy that an audi enthusiast is making these to sell.

I have learned a lot from these audiworld forums, as there a lot of smart people here, not trying to sell you anything, but provide good tips and advice, I suggest you see it in that way.

Cheers!

Great posts here, this oil coolant pipe issue is a big deal, and it is great to see so much expert advice and suggestions here - maybe it should be in the FAQ

Audinut87 - i suggest you take a good read of the comments, and maybe think twice about listening to your mechanic - yes, he may be a good wrench-turner, but is he a materials engineer? The forum comments here are well-thought and dead on.

The aluminium vs Stainless is discussion really turns on basic chemistry and physics here, no amount of marketing by gruven or any vendor can change the laws of physics... although they will try to convince you otherwise, that's why a reality-check such as is provided on these forums is so helpful.

The whole stress argument is silly at best, in a material critical environments such as in the aluminum engine, use the best material for the job, not just the strongest or lightest, or most expensive, or sexiest.

303 Stainless is a very bad idea, and most probably will cause problems, plastic was probably used as it was cheaper, obviously could not cause galvanic corrosion, and it is a very low stress (re: strength) environment, so Audi saved a few bucks, but caused problems - however, replacing it with stainless will cause additional problems. This Stainless replacement product really should not be used in the aluminum block, and any smart or well-read mechanic would appreciate that.

Also, no reason to insult the ebay seller, he provides a great product at a great price.

I am happy that an audi enthusiast is making these to sell.

I have learned a lot from these audiworld forums, as there a lot of smart people here, not trying to sell you anything, but provide good tips and advice, I suggest you see it in that way.

Cheers!

#28

BUMP for some project advice in this procedure.

I'm doing this on my 97 A8 4.2; that's what winter breaks are for- doing $1000 repair jobs on $1500 cars by yourself instead of throwing the car away.

Anyway, I'm ready to begin the re-assembly process and have a stupid question. How do the small o-rings fit in the assembly on both the short water pipe (the plastic piece which is the cause of all this fun) and on the steel pipe towards the back of the oil cooler?

With the replacement water pipe, it is unclear to me if the o-rings should go on the *ends* of the replacement water pipe and therefore be pressed into the holes in the oil cooler and engine block, or if they should somehow be stretched onto/around the water pipe itself like a washer on a bolt, and act as a ring on a piston? I should mention that I've got the aluminum replacement water pipe, which already has double o-rings on each end of it. With this piece, do I even need the other o-rings? See why I'm confused?

The same question applies to the existing metal pipe towards the back of the oil cooler. Where should the o-ring go? Inside the oil cooler's port for the pipe or around the pipe like a washer or ring on a piston?

It seems like a silly question, but it's not something I want to mess up. Not with this much effort in the project. I'm going to head back to my garage and poke around a bit.

Thanks for any help you can provide,

Dennis

I'm doing this on my 97 A8 4.2; that's what winter breaks are for- doing $1000 repair jobs on $1500 cars by yourself instead of throwing the car away.

Anyway, I'm ready to begin the re-assembly process and have a stupid question. How do the small o-rings fit in the assembly on both the short water pipe (the plastic piece which is the cause of all this fun) and on the steel pipe towards the back of the oil cooler?

With the replacement water pipe, it is unclear to me if the o-rings should go on the *ends* of the replacement water pipe and therefore be pressed into the holes in the oil cooler and engine block, or if they should somehow be stretched onto/around the water pipe itself like a washer on a bolt, and act as a ring on a piston? I should mention that I've got the aluminum replacement water pipe, which already has double o-rings on each end of it. With this piece, do I even need the other o-rings? See why I'm confused?

The same question applies to the existing metal pipe towards the back of the oil cooler. Where should the o-ring go? Inside the oil cooler's port for the pipe or around the pipe like a washer or ring on a piston?

It seems like a silly question, but it's not something I want to mess up. Not with this much effort in the project. I'm going to head back to my garage and poke around a bit.

Thanks for any help you can provide,

Dennis

#29

AudiWorld Super User

The o-rings go on the outsides of the pipes....one on the outside metal pipe (channel cut on it for this)...two on the OEM plastic pipe (one on the outside of each end).

If you bought a metal (alum) pipe (NOT oem) to replace the plastic, it should have 2 o-rings already installed on the outside of each end.

NO o-rings are installed inside any holes.

If you bought a metal (alum) pipe (NOT oem) to replace the plastic, it should have 2 o-rings already installed on the outside of each end.

NO o-rings are installed inside any holes.

#30

Thanks SIlverD2.

What threw me was the outside metal pipe. It was so messy / caked up, that I couldn't tell it had an o-ring on it until I gave it some liquid wrench and some elbow grease with a shop towel. I then had to use an exacto blade to cut it off. From there, it made sense.

Yep, have the aluminum unit with the 4 o-rings on it.

I've now got the oil cooler back installed, alternator on, airbox (with new filter), new serpentine belt, and new plugs (why not, I was in there). Tomorrow, finish the front end and fender assembly, load teh fluids, hook up the battery, pray, turn the key, observe, and pray some more.

Hopefully another 2 years, then on to an 08 or 09.

Used A8s are the best automotive bang for the buck if you've got the cojones to risk the cost of maintenance.

What threw me was the outside metal pipe. It was so messy / caked up, that I couldn't tell it had an o-ring on it until I gave it some liquid wrench and some elbow grease with a shop towel. I then had to use an exacto blade to cut it off. From there, it made sense.

Yep, have the aluminum unit with the 4 o-rings on it.

I've now got the oil cooler back installed, alternator on, airbox (with new filter), new serpentine belt, and new plugs (why not, I was in there). Tomorrow, finish the front end and fender assembly, load teh fluids, hook up the battery, pray, turn the key, observe, and pray some more.

Hopefully another 2 years, then on to an 08 or 09.

Used A8s are the best automotive bang for the buck if you've got the cojones to risk the cost of maintenance.