2006 A6 4.2 Crankshaft Position Sensor

#1

Audiworld Junior Member

Thread Starter

Join Date: Sep 2017

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

hi all,

I've been trying to replace my crankshaft position sensor on my 4.2 v8 for a while. I can't seem to find it anywhere. I was told it would be right on the bell housing when you take off the drivers side wheel well, theres nothing there. Has anyone done this and knows a step by step?

Thanks!

I've been trying to replace my crankshaft position sensor on my 4.2 v8 for a while. I can't seem to find it anywhere. I was told it would be right on the bell housing when you take off the drivers side wheel well, theres nothing there. Has anyone done this and knows a step by step?

Thanks!

#2

hi all,

I've been trying to replace my crankshaft position sensor on my 4.2 v8 for a while. I can't seem to find it anywhere. I was told it would be right on the bell housing when you take off the drivers side wheel well, theres nothing there. Has anyone done this and knows a step by step?

Thanks!

I've been trying to replace my crankshaft position sensor on my 4.2 v8 for a while. I can't seem to find it anywhere. I was told it would be right on the bell housing when you take off the drivers side wheel well, theres nothing there. Has anyone done this and knows a step by step?

Thanks!

I can't imagine it being harder on the 4.2, seeing as you claim it's located where it is.

#3

AudiWorld Member

hi there this is by elsa

Camshaft Position Sensors, Checking

This procedure is used to check Camshaft Position (CMP) Sensors -G40 and G163-.

Special tools and workshop equipment required

t Multimeter -V.A.G 1526 A- or equivalent.

t Voltage Tester -VAG1527B- or equivalent.

t Adapter Cable (121-Point) -VAG1598/31-.

t Connector Test Set -VAG1594C-.

Test requirements

l Ignition switched off.

Procedure

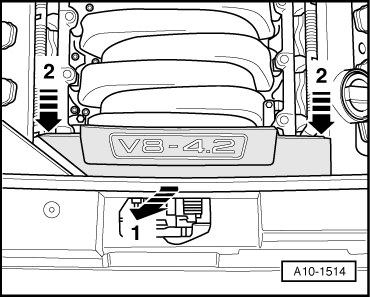

– Remove the front engine cover- arrows -1- and -2-.

– Remove the rear engine cover -arrows-.

– Disconnect the relevant Camshaft Position (CMP) Sensor electrical harness connector.

Cylinder bank 1 (right):

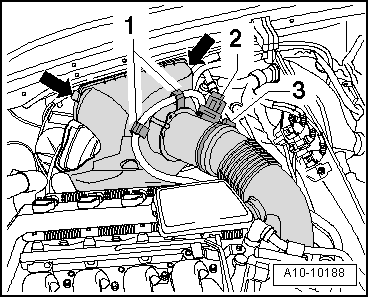

– Remove the fuel hose -1-.

– Disconnect the electrical connector -2- from the Mass Air Flow (MAF) Sensor -G70-.

– Remove the Mass Air Flow (MAF) Sensor -G70- from the air duct hose -3-.

– Remove the upper part of the air filter housing with the Mass Air Flow (MAF) Sensor -G70--arrows-.

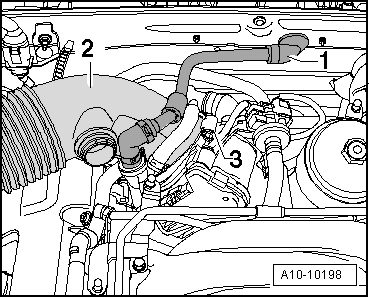

– Remove the resonator -1- in direction of the-arrow- from the air duct hose.

– Disconnect the brake booster vacuum hose -1- at the bulkhead.

– Loosen the clamp -3- and remove the air duct hose -2-.

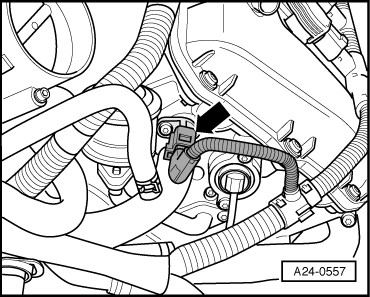

– Disconnect the electrical harness connector -arrow- from the Camshaft Position (CMP) Sensor -G40- at rear of the right cylinder head.

Cylinder bank 2 (left):

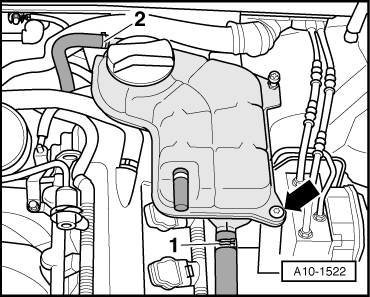

– Remove the screw -arrow- retaining the coolant reservoir.

– Disconnect the electrical connector from Engine Coolant Level (ECL) Warning Switch -F66- at the bottom of the coolant reservoir and set aside the coolant reservoir with the coolant hoses -1- and -2- connected.

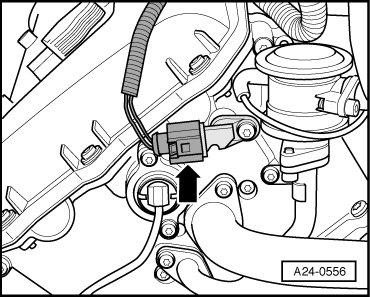

– Disconnect the electrical harness connector -arrow- from the Camshaft Position (CMP) Sensor 2 -G163- at rear of the left cylinder head.

Checking activation

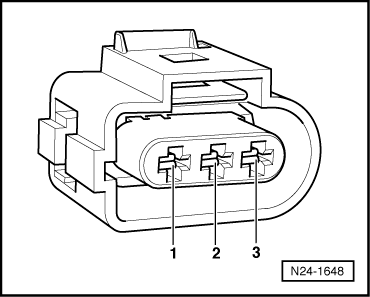

– Using the Voltage Tester -VAG1527B- or equivalent, and a probe from the Connector Test Set -VAG1594C-. Connect the Camshaft position (CMP) sensor electrical harness connector terminals 1 and 2 together and check for voltage leaving the Camshaft position (CMP) sensor electrical harness connector connected to the Camshaft position (CMP) sensor.

– Operate the starter for a few seconds.

The LED must blink.

NoteVoltage testers do not go out completely during low current pick-up between activations by the ECM, but rather continue to glow a little and then get significantly brighter during activation.

– Switch ignition off.

If the LED blinks:

– Replace the faulty Camshaft Position (CMP) Sensor.

If the LED does not blink:

Checking voltage supply

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

1 Engine Ground (GND)

– Switch the ignition on.

Specified value: about 5 V.

– Switch the ignition off.

Checking signal wire

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

2 Engine Ground (GND)

– Switch the ignition on.

Specified value: approx. battery voltage.

– Switch the ignition off.

Checking Ground (GND)

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

3 Battery positive (+)

Specified value: about 10 V.

If the specification is not obtained:

– Check the wiring for a short circuit to Battery positive (+) or an open circuit.

– If necessary, repair the wiring connection.

If no malfunction can be found:

Checking wire connections between Camshaft Position (CMP) sensor and Engine Control Module (ECM)

– Connect the Adapter Cable (121-Point) -VAG1598/31- to the wiring harness of the Engine Control Module (ECM) -J623- ; the ECM is not connected. → Chapter.

– Using the Adapter Cable (121-Point) -VAG1598/31- and Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connections for an open circuit.

l Camshaft Position (CMP) Sensor -G40- (bank 1).

Harness connector

Terminal Test box

Socket

1 Battery positive (+) 98

2 (signal) 87

3 Ground (GND) 108

l Camshaft Position (CMP) Sensor 2 -G163- (bank 2).

Harness connector

Terminal Test box

Socket

1 Battery positive (+) 98

2 (signal) 86

3 Ground (GND) 108

Specified value: Wire resistance max 1.5 Ω.

If the specification is not obtained:

– Check the wiring for a short circuit to Battery positive (+) or an open circuit.

– If necessary, repair the wiring connection.

If no malfunction can be found:

– Replace the Engine Control Module (ECM) -J623-. → Chapter.

Assembly is performed in the reverse order of removal, note the following:

Final procedures

After repair work, the following work steps must be performed in the mentioned sequence:

1 - Check the DTC memory. → Chapter.

2 - If necessary, erase the DTC memory. → Chapter.

3 - If the DTC memory was erased, generate readiness code. → Chapter.

– End diagnosis and switch ignition off.

Camshaft Position Sensors, Checking

This procedure is used to check Camshaft Position (CMP) Sensors -G40 and G163-.

Special tools and workshop equipment required

t Multimeter -V.A.G 1526 A- or equivalent.

t Voltage Tester -VAG1527B- or equivalent.

t Adapter Cable (121-Point) -VAG1598/31-.

t Connector Test Set -VAG1594C-.

Test requirements

l Ignition switched off.

Procedure

– Remove the front engine cover- arrows -1- and -2-.

– Remove the rear engine cover -arrows-.

– Disconnect the relevant Camshaft Position (CMP) Sensor electrical harness connector.

Cylinder bank 1 (right):

– Remove the fuel hose -1-.

– Disconnect the electrical connector -2- from the Mass Air Flow (MAF) Sensor -G70-.

– Remove the Mass Air Flow (MAF) Sensor -G70- from the air duct hose -3-.

– Remove the upper part of the air filter housing with the Mass Air Flow (MAF) Sensor -G70--arrows-.

– Remove the resonator -1- in direction of the-arrow- from the air duct hose.

– Disconnect the brake booster vacuum hose -1- at the bulkhead.

– Loosen the clamp -3- and remove the air duct hose -2-.

– Disconnect the electrical harness connector -arrow- from the Camshaft Position (CMP) Sensor -G40- at rear of the right cylinder head.

Cylinder bank 2 (left):

– Remove the screw -arrow- retaining the coolant reservoir.

– Disconnect the electrical connector from Engine Coolant Level (ECL) Warning Switch -F66- at the bottom of the coolant reservoir and set aside the coolant reservoir with the coolant hoses -1- and -2- connected.

– Disconnect the electrical harness connector -arrow- from the Camshaft Position (CMP) Sensor 2 -G163- at rear of the left cylinder head.

Checking activation

– Using the Voltage Tester -VAG1527B- or equivalent, and a probe from the Connector Test Set -VAG1594C-. Connect the Camshaft position (CMP) sensor electrical harness connector terminals 1 and 2 together and check for voltage leaving the Camshaft position (CMP) sensor electrical harness connector connected to the Camshaft position (CMP) sensor.

– Operate the starter for a few seconds.

The LED must blink.

NoteVoltage testers do not go out completely during low current pick-up between activations by the ECM, but rather continue to glow a little and then get significantly brighter during activation.

– Switch ignition off.

If the LED blinks:

– Replace the faulty Camshaft Position (CMP) Sensor.

If the LED does not blink:

Checking voltage supply

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

1 Engine Ground (GND)

– Switch the ignition on.

Specified value: about 5 V.

– Switch the ignition off.

Checking signal wire

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

2 Engine Ground (GND)

– Switch the ignition on.

Specified value: approx. battery voltage.

– Switch the ignition off.

Checking Ground (GND)

– Using the Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connection for voltage:

Harness connector

Terminal Measure to

3 Battery positive (+)

Specified value: about 10 V.

If the specification is not obtained:

– Check the wiring for a short circuit to Battery positive (+) or an open circuit.

– If necessary, repair the wiring connection.

If no malfunction can be found:

Checking wire connections between Camshaft Position (CMP) sensor and Engine Control Module (ECM)

– Connect the Adapter Cable (121-Point) -VAG1598/31- to the wiring harness of the Engine Control Module (ECM) -J623- ; the ECM is not connected. → Chapter.

– Using the Adapter Cable (121-Point) -VAG1598/31- and Multimeter -V.A.G 1526 A- or equivalent, check the following wiring connections for an open circuit.

l Camshaft Position (CMP) Sensor -G40- (bank 1).

Harness connector

Terminal Test box

Socket

1 Battery positive (+) 98

2 (signal) 87

3 Ground (GND) 108

l Camshaft Position (CMP) Sensor 2 -G163- (bank 2).

Harness connector

Terminal Test box

Socket

1 Battery positive (+) 98

2 (signal) 86

3 Ground (GND) 108

Specified value: Wire resistance max 1.5 Ω.

If the specification is not obtained:

– Check the wiring for a short circuit to Battery positive (+) or an open circuit.

– If necessary, repair the wiring connection.

If no malfunction can be found:

– Replace the Engine Control Module (ECM) -J623-. → Chapter.

Assembly is performed in the reverse order of removal, note the following:

Final procedures

After repair work, the following work steps must be performed in the mentioned sequence:

1 - Check the DTC memory. → Chapter.

2 - If necessary, erase the DTC memory. → Chapter.

3 - If the DTC memory was erased, generate readiness code. → Chapter.

– End diagnosis and switch ignition off.

Thread

Thread Starter

Forum

Replies

Last Post

Charly1215

A6 / S6 (C6 Platform) Discussion

0

11-22-2017 08:49 AM

gateway

A6 / S6 (C6 Platform) Discussion

0

12-02-2012 11:09 AM