Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Air Intake and Exhaust Guides

- Audi A6 C6 3.2L V6: How to Inspect and Clean Intake Valve Carbon Deposits

Step by step instructions for do-it-yourself repairs

Browse all: Air Intake and Exhaust Guides

3.2L FSI, How to inspect carbon deposit on intake valves and clean it

#61

Thanks for the reply. Using the crankshaft adapter tool and a really long torque wrench I was able to rotate quite easily. I pulled the spark plugs which did help and I was rotating towards the driver's side, or clockwise from my perspective at the front of the car. It didn't take long for the other two (2 & 5) to close, and a few others stayed closed as well. It seems like they stay in the closed position for a little bit, and I could hear them closing rubbing on the carbon buildup as they closed, so I wasn't too worried about turning the crank to just one sweet spot.

Being from Canada this reminded me a little of scraping ice off the windshield so I used a small tool that came with a soldering kit I had. As it was flat it made the job go a bit quicker. The long red 90 degree scraper came in handy to get a lot of it off, and then the other end which is straight was good to clean the tops of the valves themselves and clean up around the edges. I had a curved pick but I didn't find that one very useful.

Soaking in brake cleaner for 30 - 60 min, vacuuming it up (put shop towel over the cylinder head or fluid will start to fly out), and letting it dry overnight helped a lot. I did this twice on each cylinder so far but I may go back for a third.

I ordered injector repair kits off ebay. They came with the o-ring but I don't think they have the split spacer piece. It should be ok to re-use the spacer as long as I am putting new O-rings with some clean oil on right?

Update 02/09:

I am in the process of putting things back together. One thing I will mention that I don't think in the writeup would be to take the throttle body off the upper intake, give it a cleaning and replace the throttle body gasket. Finally, after everything is done use VCDS to align the throttle body.

As per ross tech website: Throttle Body Alignment (TBA) - Ross-Tech Wiki)

Turn the key on but do not start the car.

[Select]

[01 - Engine]

[Basic Settings - 04]

Group 060

[Go!]

It should say "Basic Settings: OFF" on the top of your screen.

Click [ON/OFF/Next] to turn on Basic Settings.

It should now say "Basic Settings: ON" on the top of your screen. Once you do this you will see the top right display say ADP RUN. The TB adaptation is being done as soon as you switched basic settings on. You will see the values change and hear the TB cycle for the first few seconds then it will stop. Leave it in Basic Settings for about 30 seconds.

Click [ON/OFF/Next] to turn off Basic Settings.

It should now say "Basic Settings: OFF" on the top of your screen

Click the [Done, Go Back] button and you're all set.

Be sure not to touch the accelerator and make sure the engine is NOT running when you do this!

I am also replacing my fuel filter since the system is already de-pressurized (see 55K thread for instructions). I've also read somewhere to turn the key to on, and let it sit for a few seconds, then off, repeat a few times in order to fully pressurize the fuel system before actually firing the engine back up - probably not necessary but I thought it made sense.

Being from Canada this reminded me a little of scraping ice off the windshield so I used a small tool that came with a soldering kit I had. As it was flat it made the job go a bit quicker. The long red 90 degree scraper came in handy to get a lot of it off, and then the other end which is straight was good to clean the tops of the valves themselves and clean up around the edges. I had a curved pick but I didn't find that one very useful.

Soaking in brake cleaner for 30 - 60 min, vacuuming it up (put shop towel over the cylinder head or fluid will start to fly out), and letting it dry overnight helped a lot. I did this twice on each cylinder so far but I may go back for a third.

I ordered injector repair kits off ebay. They came with the o-ring but I don't think they have the split spacer piece. It should be ok to re-use the spacer as long as I am putting new O-rings with some clean oil on right?

Update 02/09:

I am in the process of putting things back together. One thing I will mention that I don't think in the writeup would be to take the throttle body off the upper intake, give it a cleaning and replace the throttle body gasket. Finally, after everything is done use VCDS to align the throttle body.

As per ross tech website: Throttle Body Alignment (TBA) - Ross-Tech Wiki)

Turn the key on but do not start the car.

[Select]

[01 - Engine]

[Basic Settings - 04]

Group 060

[Go!]

It should say "Basic Settings: OFF" on the top of your screen.

Click [ON/OFF/Next] to turn on Basic Settings.

It should now say "Basic Settings: ON" on the top of your screen. Once you do this you will see the top right display say ADP RUN. The TB adaptation is being done as soon as you switched basic settings on. You will see the values change and hear the TB cycle for the first few seconds then it will stop. Leave it in Basic Settings for about 30 seconds.

Click [ON/OFF/Next] to turn off Basic Settings.

It should now say "Basic Settings: OFF" on the top of your screen

Click the [Done, Go Back] button and you're all set.

Be sure not to touch the accelerator and make sure the engine is NOT running when you do this!

I am also replacing my fuel filter since the system is already de-pressurized (see 55K thread for instructions). I've also read somewhere to turn the key to on, and let it sit for a few seconds, then off, repeat a few times in order to fully pressurize the fuel system before actually firing the engine back up - probably not necessary but I thought it made sense.

Last edited by DreewMcK; 02-16-2016 at 06:43 PM. Reason: revised throttle body adaptation procedure

#62

I never said to remove the injectors, and luckily they stayed put in the head. O-rings between injectors and lower intakes are the main things to replace. However, I don't know the design detail of fuel rail and injector and function of the split o-rings. I have never seen that type of construction, and don't know enough to recommend to replace just o-rings because the high fuel pressure can reach up to 1500 psi.

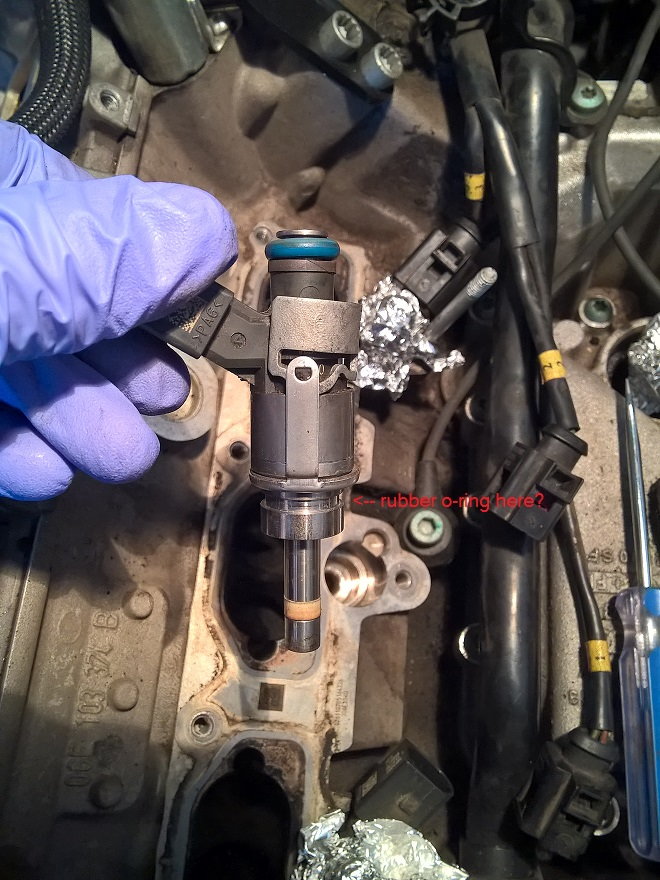

It looks like there is a rubber ring that needs to go between the the injector and the head. But I couldn't find it anywhere. I don't want to take out another injector, firstly because they are really hard to come off and secondly I want to minimise the risk of leaking injector.

Can you guys please shed some light on how install the injector properly and if there is a rubber o-ring between the injector and head block? Thanks.

#63

Hi, I'm wondering if you guys can help me. When I removed my fuel lower intake manifold, one fuel injector came with it and came off from engine head block. I tried to insert it again, but it just doesn't sit tight and feel secured. I can still take it off easily.

It looks like there is a rubber ring that needs to go between the the injector and the head. But I couldn't find it anywhere. I don't want to take out another injector, firstly because they are really hard to come off and secondly I want to minimise the risk of leaking injector.

Can you guys please shed some light on how install the injector properly and if there is a rubber o-ring between the injector and head block? Thanks.

It looks like there is a rubber ring that needs to go between the the injector and the head. But I couldn't find it anywhere. I don't want to take out another injector, firstly because they are really hard to come off and secondly I want to minimise the risk of leaking injector.

Can you guys please shed some light on how install the injector properly and if there is a rubber o-ring between the injector and head block? Thanks.

If you purchase an injector repair kit it will have all the parts required for replacement on the injector, though to put the Teflon seal in place, you need 4 special tools just to put the ring on.

I suggest the reason the injector came out is that the support ring and /or radial adjustment clip may not have been in the proper positions as they work to hold the injector in the head.

Last edited by Audishiva; 04-28-2016 at 06:25 AM.

#65

I am looking in the Bentley manual at page 24-18 which shows the exploded diagram of the 3.2L injector. It does not show an o-ring on the lower part but the diagram is slightly different from your picture. There is no ring and ridge on the injector in the diagram. It is unlikely there would be an o-ring due to temperatures so I would think the reason for the injector not fitting properly is that the Teflon ring is damaged on the injector nose. Normally, it is a snug fit in the bore hole.

If you purchase an injector repair kit it will have all the parts required for replacement on the injector, though to put the Teflon seal in place, you need 4 special tools just to put the ring on.

I suggest the reason the injector came out is that the support ring and /or radial adjustment clip may not have been in the proper positions as they work to hold the injector in the head.

If you purchase an injector repair kit it will have all the parts required for replacement on the injector, though to put the Teflon seal in place, you need 4 special tools just to put the ring on.

I suggest the reason the injector came out is that the support ring and /or radial adjustment clip may not have been in the proper positions as they work to hold the injector in the head.

I put everything back together. The engine run well enough. But I notice idle is a bit rough. Note that I've replaced all spark plugs and ignition coils. So maybe, there is a very small leak from the injector(s) that affects the compression. I'll check the cylinders' compression and perhaps replace the injectors' components using the repair kit. I'll give another update after.

You mentioned about the special tool to replace the teflon seal. Can you elaborate please? Thank you.

#66

Nice writeup, what is the vacuum pipe that comes put of the intake pipe for? In this writeup it says brake booster vacuum bit there are two pipes? The upper one that goes into the intake pipe just before the throttle body has broke on mine.

#67

AudiWorld Member

Thread Starter

#69

There are 4 tools required just to install the Teflon seal correctly. T10133/5, /6, /7 and/8 and then a fifth one T10133/9 (not illustrated) to push the completed injector into place.

If you can afford to not have the car for a day, perhaps an Audi/VW/Porsche specialist or even a Bosch injector service shop could install the injector seals for you on the two that are messed up.

#70

Audishiva and boldenwell, i'll be attempting this this weekend. I have to change an injector due to error code:

I bought an injector and an injector replacing kit. I don't quite understand what you are saying about the injector teflon taping? Can you elaborate please?

Thanks!

Code:

Wednesday,08,June,2016,15:42:51:55111

VCDS -- Windows Based VAG/VAS Emulator Running on Windows 10 x64

VCDS Version: 15.7.4.1 (x64)

Data version: 20160216

www.Ross-Tech.com

VIN: XXXXXXXXXXXXXXXXX License Plate:

Mileage: 201810km-125398mi Repair Order:

Chassis Type: 8E (8E - Audi A4/S4/RS4 B6/B7 (2001 > 2008))

Scan: 01 02 03 08 09 0F 11 15 16 17 18 25 36 37 45 46 55 56 57 65

67 69 75 76 77

VIN: XXXXXXXXXXXXXXXXX Mileage: 201810km-125398miles

-------------------------------------------------------------------------------

Address 01: Engine (AUK) Labels: 06E-910-559-BKH.lbl

Part No SW: 8E1 910 559 F HW: 8E0 907 559 J

Component: 3.2l V6 FSI 0080

Revision: --H19--- Serial number:

Coding: 01040109190F0120

Shop #: WSC 93009 999 04862

VCID: 3169D31DA8FE1DB6C1-8064

4 Faults Found:

004376 - Oxygen (Lambda) Sensor Heating; B1 S2

P1118 - 009 - Open Circuit - Intermittent

Freeze Frame:

Fault Status: 00000100

Fault Priority: 4

Fault Frequency: 1

Reset counter: 27

Mileage: 201623 km

Time Indication: 0

Freeze Frame:

RPM: 768 /min

Mass Air / Rev.: 109.0 mg/str

Temperature: 91.5°C

Idle

Voltage: 13.87 V

Bin. Bits: 00000010

008304 - Intake Manifold Tuning Valve (Bank 1)

P2070 - 006 - Stuck Open - Intermittent

Freeze Frame:

Fault Status: 00100001

Fault Priority: 2

Fault Frequency: 1

Reset counter: 28

Mileage: 201623 km

Time Indication: 0

Freeze Frame:

RPM: 768 /min

Mass Air / Rev.: 114.5 mg/str

Temperature: 91.5°C

Idle

Absolute Pres.: 340.5 mbar

Speed: 0.0 km/h

000611 - Fuel Injector #1 (N30)

P0263 - 007 - Contribution/Balance Fault

Freeze Frame:

Fault Status: 00100010

Fault Priority: 2

Fault Frequency: 1

Reset counter: 40

Mileage: 201623 km

Time Indication: 0

Freeze Frame:

RPM: 768 /min

Mass Air / Rev.: 109.0 mg/str

Temperature: 91.5°C

Idle

Load: 15.7 %

Speed: 0.0 km/h

004407 - Fuel Trim: Bank 1 (Add)

P1137 - 007 - System too Rich - MIL ON

Freeze Frame:

Fault Status: 10100010

Fault Priority: 6

Fault Frequency: 3

Reset counter: 40

Mileage: 201710 km

Time Indication: 0

Freeze Frame:

RPM: 768 /min

Mass Air / Rev.: 169.0 mg/str

Temperature: 91.5°C

Idle

Time: 1433.6 s

Bin. Bits: 00000010

Thanks!