Audi UR Quattro Rally Build

#31

AudiWorld Member

Thread Starter

This concept of refurbishing parts then bolting them to the unpainted shell is working out well as we have already discovered a few things we need to mod and are accumulating quite a parts list too.

We got our first batch of parts back from powder coating:

And wasted no time attaching some of them to the car. Front sub=frame for instance:

We also received a Sparco battery cut-off for the dash:

Our friend Paull is concurrently building an RS200 replica with a Focus RS crate engine. He brought over his superfluous factory intercooler to see if it might work for our application. Maybe:

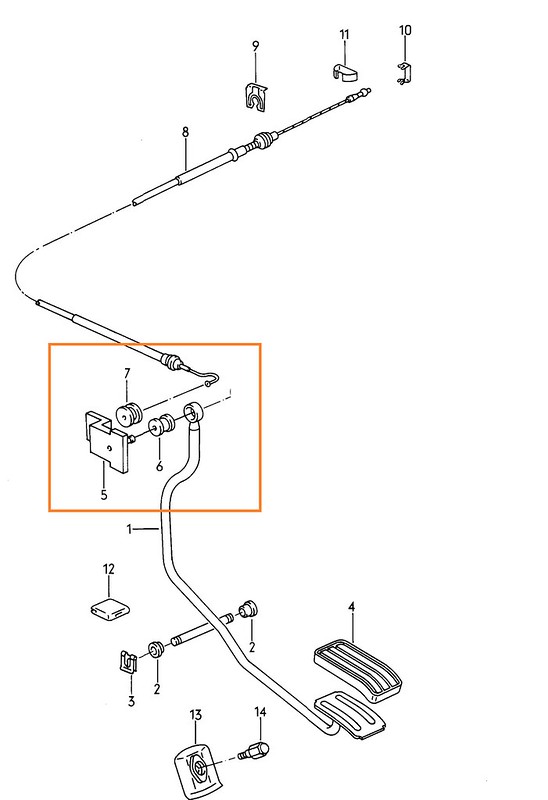

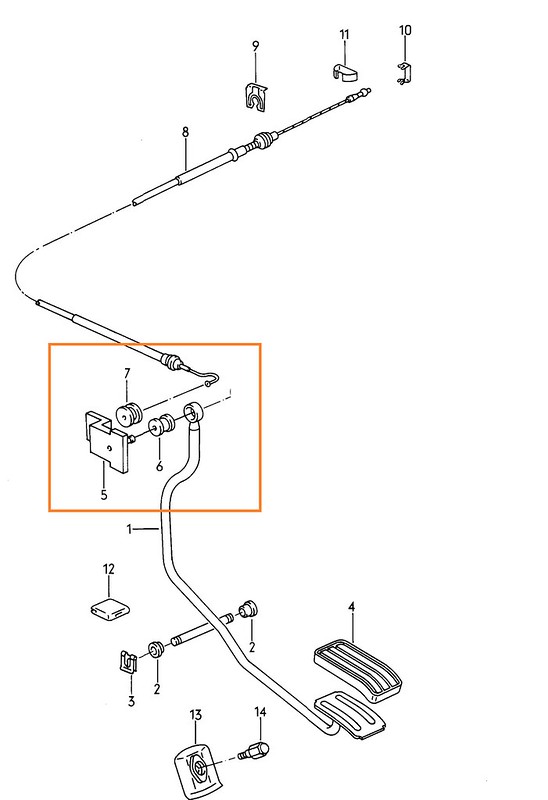

We finished the refurb on the steering column but it is going to need a bushing sleeve replaced before being put into actual service. However, this didn’t stop us bolting it up along with the refurbished pedal assembly:

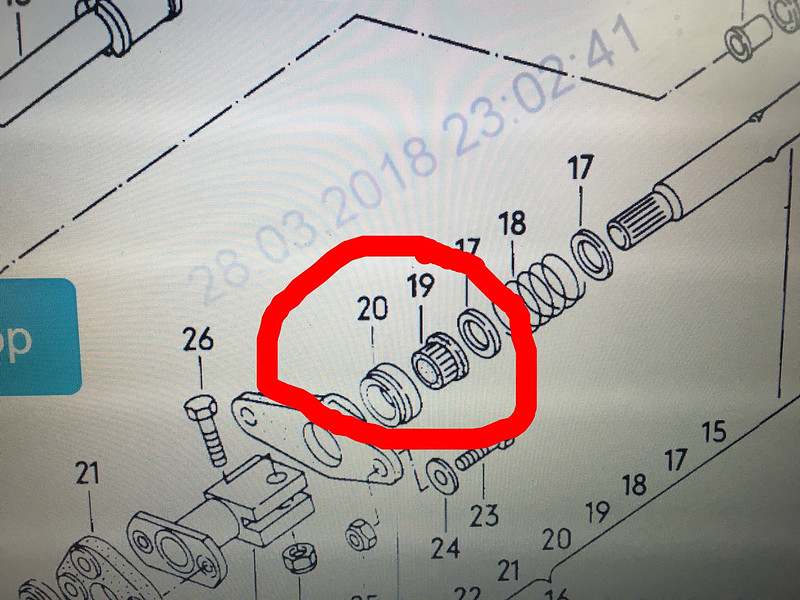

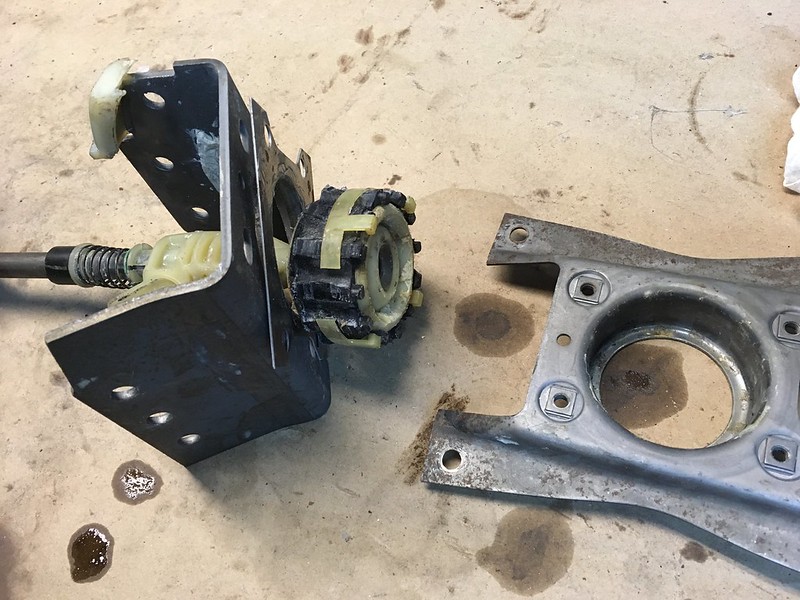

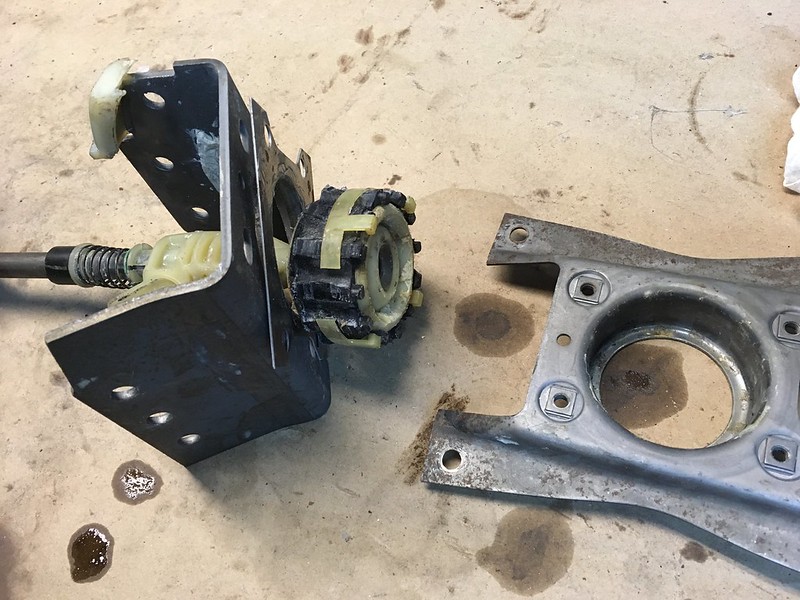

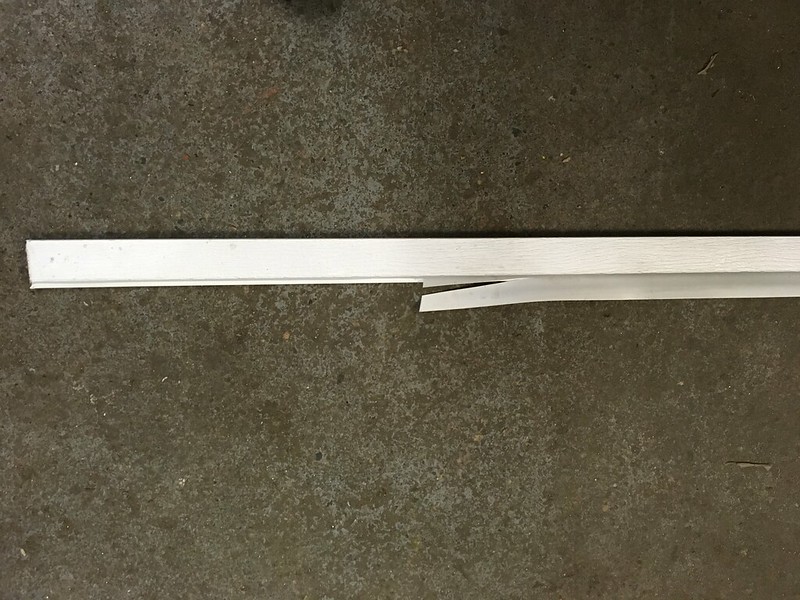

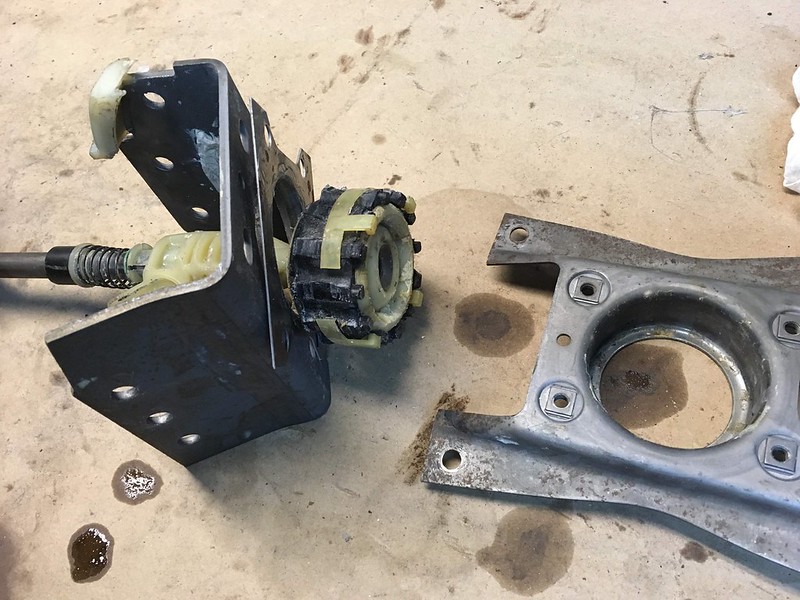

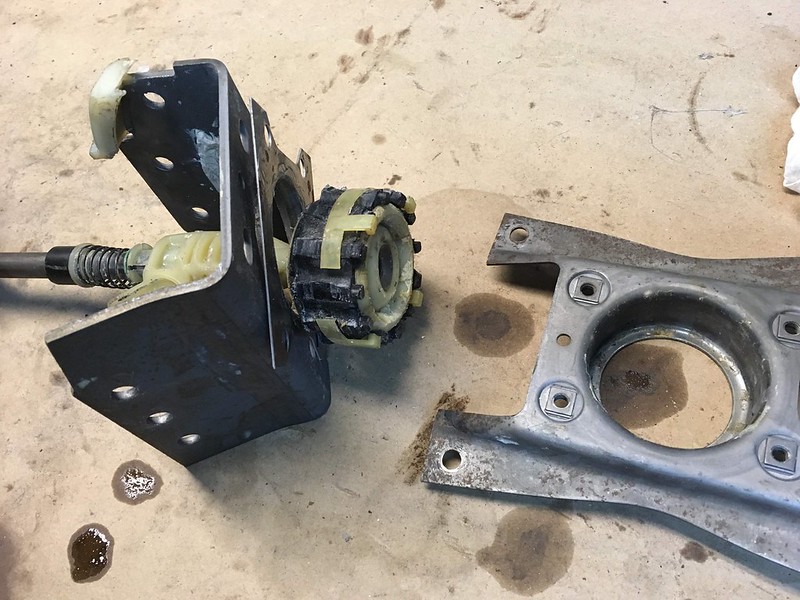

We thought our pedal assembly was in pretty good shape, until we took the over-center spring apart to clean it:

Add that to the parts list. Stll, it didn’t stop us bolting it to the car:

We also spent a bit of time prepping some parts for plating. We are having this lot zinc dichromated so they need sand blasting first. It was suggested filling the cylinder bores with hot glue so they wouldn’t get sand blasted so we gave it a try.

We took the opportunity to test fit the dash as we suspected it would interfere with the steering column. We were not wrong. There’s a reason for that cutout after all:

We plan to continue to assemble the car this coming week so look for an update soon.

Last edited by team illuminata; 04-01-2018 at 03:39 PM.

#32

AudiWorld Member

Thread Starter

TOO MANY FRONTS!

What do we mean by “fronts”. Well, we have opened up quite a few areas of work on the car, none of which seem to be nearing completion: namely:

• transmission,

• plating

• pedals

• dash

• shifter

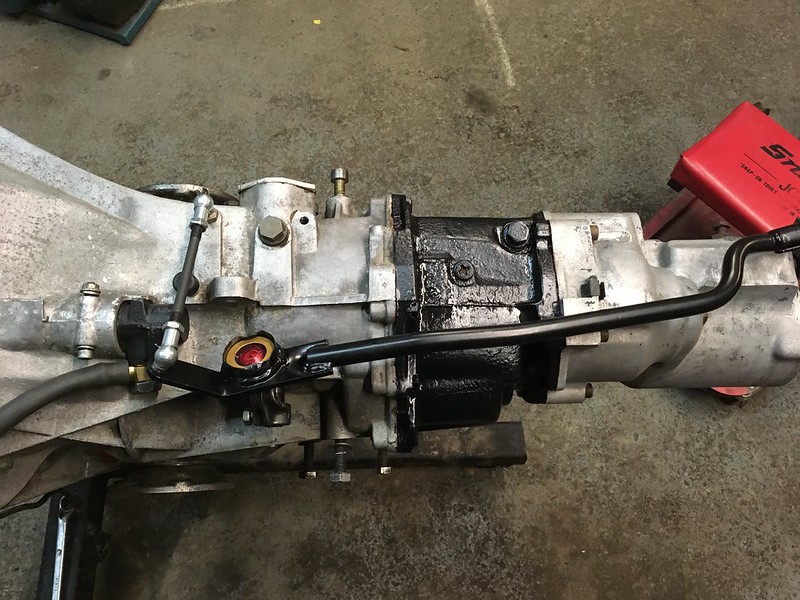

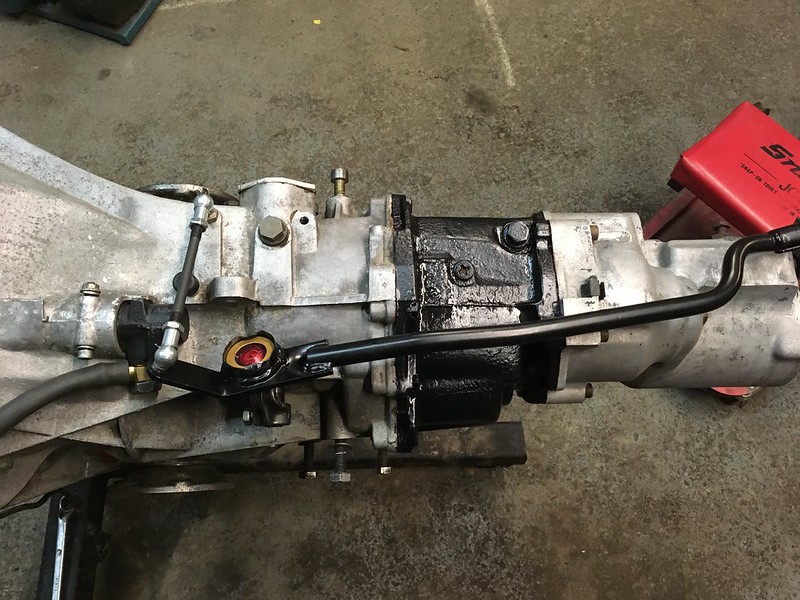

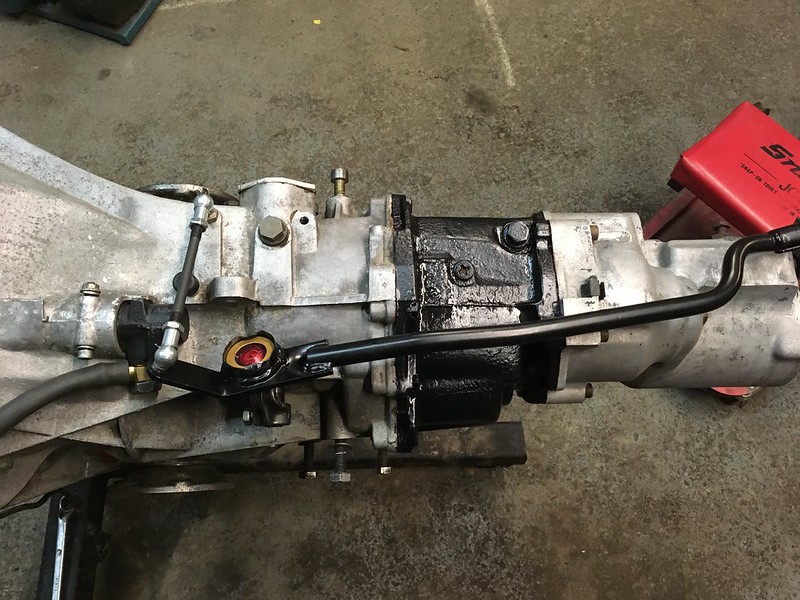

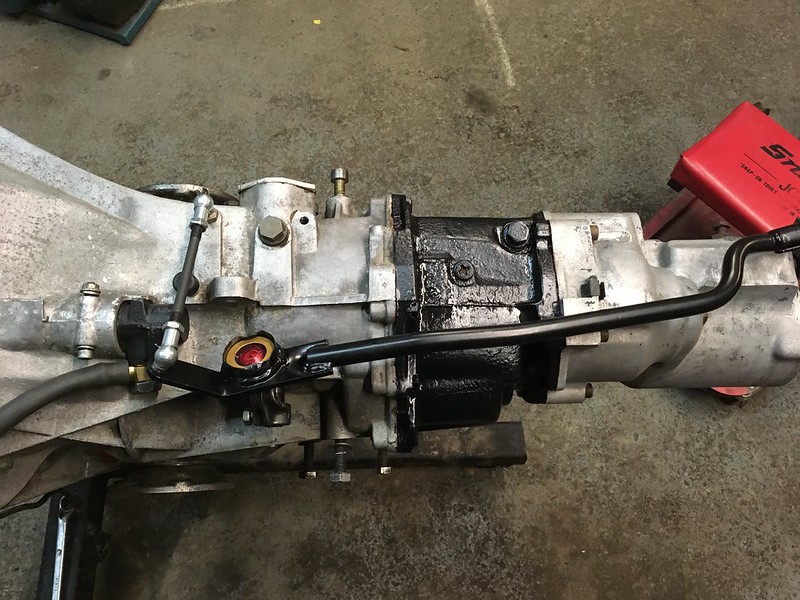

We have power washed the transmission and replaced axle seals but we broke a tab off the rear output unit and only just found a spare transmission to steal one off. Now we will disassemble that and replace both seals. Fortunately the bearing in this one is in great shape so it actually saved us some money and time.

[/url]

[/url]

Still have to clean the trans and replace the input seal. Then install the shift linkage we recently refurbished.

Along with the calipers we prepped for plating we also have dozens of fasteners and brackets to re-plate. To help with the cleaning process we bought a vibrating parts cleaner from Harbor Freight. We are still learning what media works best for what degree of rust etc.

We did make some progress with the shifter in that we managed to disassemble it. Without breaking anything either!

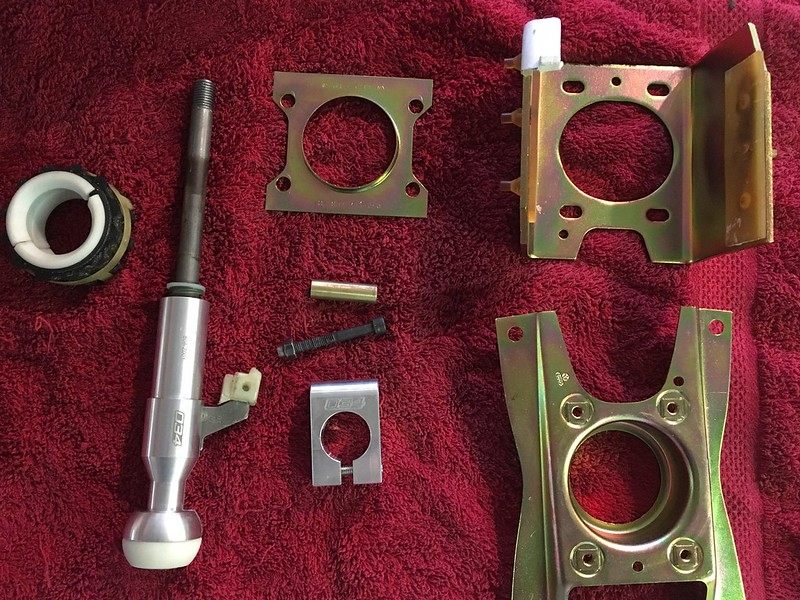

The reverse lock-out tab is bent but otherwise it’s OK. We ordered a short shift kit from 034 Motorsports for it too

We laid down some plywood floorboards after installing the pedals. The floor was very uncomfortable to kneel on and our work boots made it dirty. This will be a lot more convivial.

We still need to find the accelerator pedal, get the dash to fit over the steering column and also fill it with gauges and switches.

Lots to do!

What do we mean by “fronts”. Well, we have opened up quite a few areas of work on the car, none of which seem to be nearing completion: namely:

• transmission,

• plating

• pedals

• dash

• shifter

We have power washed the transmission and replaced axle seals but we broke a tab off the rear output unit and only just found a spare transmission to steal one off. Now we will disassemble that and replace both seals. Fortunately the bearing in this one is in great shape so it actually saved us some money and time.

[/url]

[/url]Still have to clean the trans and replace the input seal. Then install the shift linkage we recently refurbished.

Along with the calipers we prepped for plating we also have dozens of fasteners and brackets to re-plate. To help with the cleaning process we bought a vibrating parts cleaner from Harbor Freight. We are still learning what media works best for what degree of rust etc.

We did make some progress with the shifter in that we managed to disassemble it. Without breaking anything either!

The reverse lock-out tab is bent but otherwise it’s OK. We ordered a short shift kit from 034 Motorsports for it too

We laid down some plywood floorboards after installing the pedals. The floor was very uncomfortable to kneel on and our work boots made it dirty. This will be a lot more convivial.

We still need to find the accelerator pedal, get the dash to fit over the steering column and also fill it with gauges and switches.

Lots to do!

#33

AudiWorld Member

Thread Starter

We made quite a lot of progress this week but it doesn’t feel like it. Perhaps because we didn’t get to actually bolt anything to the car. What we did do was finish prepping the transmission. We replaced the rear coupling and seals with a non-broken version, cleaned and painted the case, installed new drain and fill plugs, replaced the input shaft seal and installed the mounts and brackets. Mounts are 034 Motorsport in Delrin.

People keep telling us we really need to run with the big, heavy rubber damper mounted to the back of the transmission as Audi intended but we’d really rather leave it off. Are we nuts?

We also managed to recommission our ancient, homebuilt sand blaster and put it to work on some rusty components. Unfortunately, in our excited state, we forgot to take the “before” pictures.

Next week we hope to modify the dash to fit over the steering column and get some parts plated. We will also look for something to bolt to the car. Exciting!!!!!!!

People keep telling us we really need to run with the big, heavy rubber damper mounted to the back of the transmission as Audi intended but we’d really rather leave it off. Are we nuts?

We also managed to recommission our ancient, homebuilt sand blaster and put it to work on some rusty components. Unfortunately, in our excited state, we forgot to take the “before” pictures.

Next week we hope to modify the dash to fit over the steering column and get some parts plated. We will also look for something to bolt to the car. Exciting!!!!!!!

#34

AudiWorld Member

Thread Starter

Like most car nuts we are easily distracted by shiny things that come in the mail. This week was particularly distracting in that regard:

Clutch bulkhead brace from 034 Motorsports:

Solid Delrin engine mounts from 034 Motorsports:

Transmission mounts from 034 Motorsports:

[/url]

[/url]

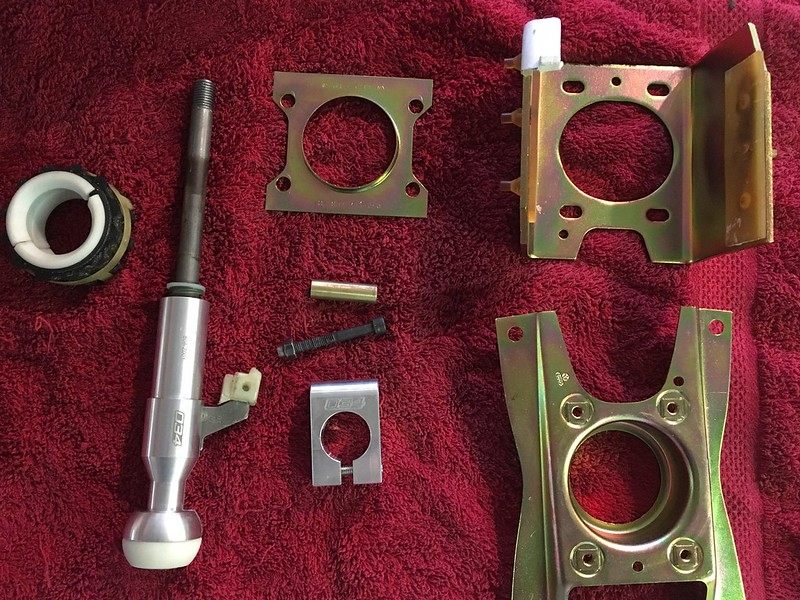

Short shift kit from 034 Motorsport (of course):

We also gave the car its own "woom" to gestate in. Do you think it will be ready in nine months?

Next up. Hacking up the dash to make it fit.

Clutch bulkhead brace from 034 Motorsports:

Solid Delrin engine mounts from 034 Motorsports:

Transmission mounts from 034 Motorsports:

[/url]

[/url]Short shift kit from 034 Motorsport (of course):

We also gave the car its own "woom" to gestate in. Do you think it will be ready in nine months?

Next up. Hacking up the dash to make it fit.

#35

AudiWorld Member

Thread Starter

It’s time to make the Group B rally dash actually fit in the car. This is a reproduction panel modelled on an original by a member of the US Quattro community and is beautifully crafted. Unfortutunately they have to be “relieved” to fit round the steering column as the lower return is supplied straight. You can’t just cut it as it would then be too flimsy. An added complication is that we intend to still use the ignition key so we have to make room for the barrel housing too. You can see the interference here:

That bottom flange needs to follow the curvature of the panel. To do so it needs to be cut, formed and then a bridge piece added to maintain its rigidity. Then we will need to remove some material to clear the lock. We will have to do all this with the gauge panel in place or it will easily distort.

These fasteners will be replaced with rivets once we are confident everything fits.

Then we needed to clear the ignition key housing:

The dash panel is suspended from the dash bar welded between the cage A pillar bars but will need some bracing beneath to stop it swinging back and forth. We fabricated these brackets and used the holes from the old cage to help mount them.

Done!

Now to mount some more gauges, fuses and a computer!

(These are just a small selection of the pictures we have taken. You can see all of them at https://flic.kr/s/aHskqskKvZ)

That bottom flange needs to follow the curvature of the panel. To do so it needs to be cut, formed and then a bridge piece added to maintain its rigidity. Then we will need to remove some material to clear the lock. We will have to do all this with the gauge panel in place or it will easily distort.

These fasteners will be replaced with rivets once we are confident everything fits.

Then we needed to clear the ignition key housing:

The dash panel is suspended from the dash bar welded between the cage A pillar bars but will need some bracing beneath to stop it swinging back and forth. We fabricated these brackets and used the holes from the old cage to help mount them.

Done!

Now to mount some more gauges, fuses and a computer!

(These are just a small selection of the pictures we have taken. You can see all of them at https://flic.kr/s/aHskqskKvZ)

#36

AudiWorld Member

Thread Starter

Gauging progress on the Quattro Rally Build.

The dash on the Group B Quattros is somewhat iconic especially the big orange oil light in the middle. For this reason we have been very keen to progress work in this area.

Our large tachometer came without any mounting hardware. It looks like it was designed to mount into a rubber grommet like the Porsche 911 gauges. That was never going to work with the 2mm thick aluminium dash we are working with so we had to get creative. First we tried a large hose clamp but of course it rattled around.

Then we butchered some garage door seal for its rubber and tried that under the hose clamp.

This worked as the clamp squeezed itself up against the back of the dash but didn’t really look the part. We found a roll of thicker black seal in the back of the shop and sliced that up instead. Success!

Then our missing VDO gauges came in from egauges.com so we mounted them up. The threaded sleeve on these makes installation so much easier than the yoke and thumb nuts of old.

Our tachometer came without mounting studs but no yoke so we made one.

Then we just had to put it into the car.

All it needs now is warning lights and switches, mostly.

We were also very excited to receive a box of metric flange nuts and bolts we found on eBay. These will be very useful.

Yes, we know, we’re nuts!

The dash on the Group B Quattros is somewhat iconic especially the big orange oil light in the middle. For this reason we have been very keen to progress work in this area.

Our large tachometer came without any mounting hardware. It looks like it was designed to mount into a rubber grommet like the Porsche 911 gauges. That was never going to work with the 2mm thick aluminium dash we are working with so we had to get creative. First we tried a large hose clamp but of course it rattled around.

Then we butchered some garage door seal for its rubber and tried that under the hose clamp.

This worked as the clamp squeezed itself up against the back of the dash but didn’t really look the part. We found a roll of thicker black seal in the back of the shop and sliced that up instead. Success!

Then our missing VDO gauges came in from egauges.com so we mounted them up. The threaded sleeve on these makes installation so much easier than the yoke and thumb nuts of old.

Our tachometer came without mounting studs but no yoke so we made one.

Then we just had to put it into the car.

All it needs now is warning lights and switches, mostly.

We were also very excited to receive a box of metric flange nuts and bolts we found on eBay. These will be very useful.

Yes, we know, we’re nuts!

Last edited by team illuminata; 05-31-2018 at 01:17 PM.

#37

AudiWorld Member

Thread Starter

We took our first foray into replating components recently. Many steel components on 80s German cars have a gold finish which was at the time probably cadmium plating. These days, due to EPA regulations, zinc dichromate plating seems to be a better option. You can do it in-house quite easily but the dichromate part is really toxic so we prefer to have it done as far away from our shop as practicable. We have also resisted the temptation to lick the newly finished parts.

First step in the process is to degrease the components and then to remove all the rust by blasting. As we mentioned earlier, we recently recommissioned our home-made sand blaster so used that to blast a bunch of accumulated parts.

We boxed them up and ran them over to Plating Specialists Inc. in Madison Heights. A safe 15 miles from our shop. Two weeks and $240 later WOW:

We couldn’t help but bolt a few components to the car:

We think we might be addicted to zinc dichromate plating now.

First step in the process is to degrease the components and then to remove all the rust by blasting. As we mentioned earlier, we recently recommissioned our home-made sand blaster so used that to blast a bunch of accumulated parts.

We boxed them up and ran them over to Plating Specialists Inc. in Madison Heights. A safe 15 miles from our shop. Two weeks and $240 later WOW:

We couldn’t help but bolt a few components to the car:

We think we might be addicted to zinc dichromate plating now.

#38

AudiWorld Member

Thread Starter

SHORT SHIFTER

We mentioned earlier that we had purchased a short shift kit from 034 Motorsports. Well, with our freshly plated shifter components back at the shop we wasted no time in assembling it and bolting it in. This is the stock shifter:

And the freshly plated components and short shift kit jigsaw puzzle:

We soon had it together:

And bolted in the car:

Of course the transmission is not in so the shift rod is just hanging in space for now.

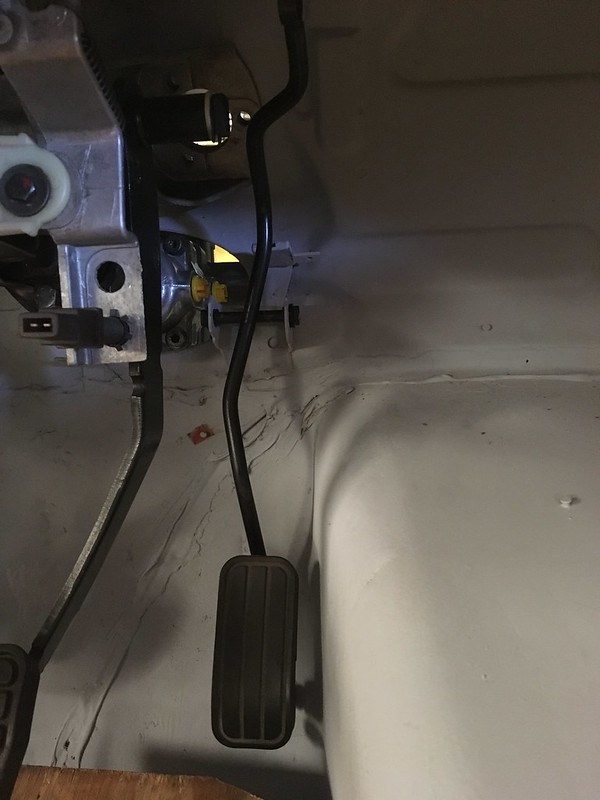

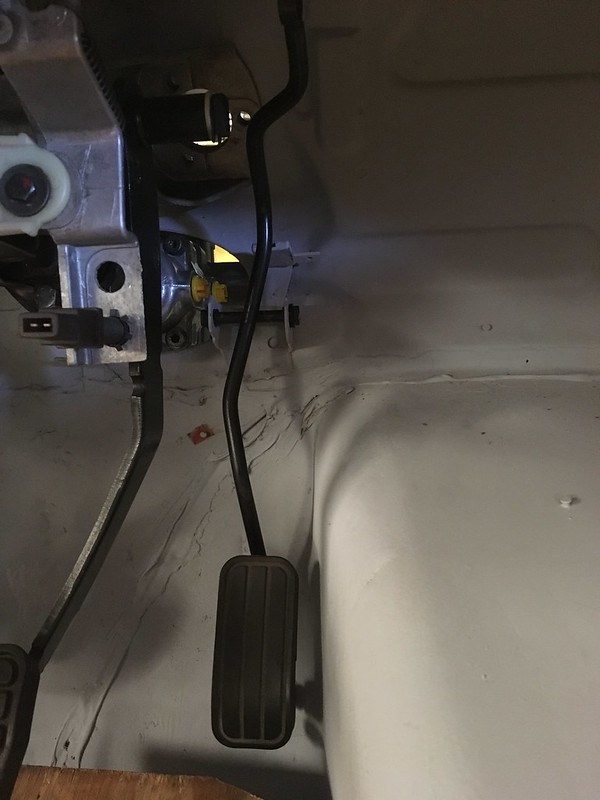

GAS PEDAL

During or shifter assembling we stumbled upon the gas pedal. We knew it couldn’t evade us forever. The pivot bushings seemed fine so we quickly slapped it in the car and made VROOM - VROOM noises.

We are not sure if we are going to employ the original method of connecting the accelerator cable though. Seems a bit weird.

After all that hard work we felt we deserved a sit down and a nice cup of tea:

We mentioned earlier that we had purchased a short shift kit from 034 Motorsports. Well, with our freshly plated shifter components back at the shop we wasted no time in assembling it and bolting it in. This is the stock shifter:

And the freshly plated components and short shift kit jigsaw puzzle:

We soon had it together:

And bolted in the car:

Of course the transmission is not in so the shift rod is just hanging in space for now.

GAS PEDAL

During or shifter assembling we stumbled upon the gas pedal. We knew it couldn’t evade us forever. The pivot bushings seemed fine so we quickly slapped it in the car and made VROOM - VROOM noises.

We are not sure if we are going to employ the original method of connecting the accelerator cable though. Seems a bit weird.

After all that hard work we felt we deserved a sit down and a nice cup of tea:

#39

AudiWorld Member

Thread Starter

It’s been a while since we got to work on the rally Quattro project so also a while since any updates. We have been distracted by other projects such as getting our 85 Quattro ready for the Concours D’elegance of America towards the end of July. Happily the car won an award so it was worth the effort.

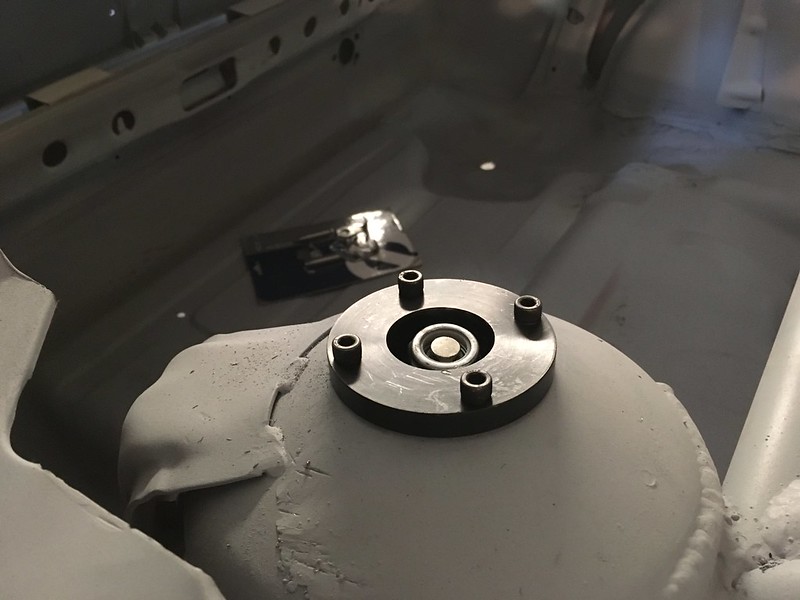

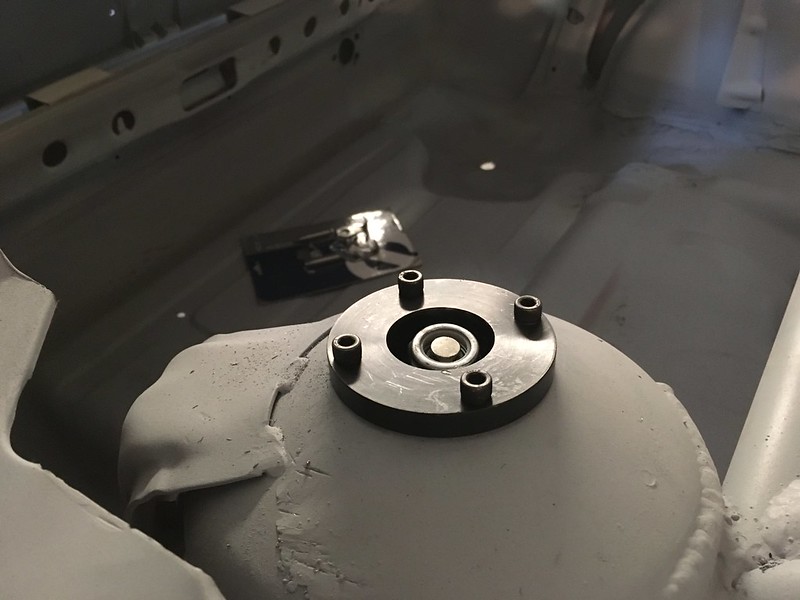

As you may recall the car came with some suspension parts, the origin of which we could not determine. Namely: delrin control arm bushings, coil-over conversion kit and spherical bearing top mounts.

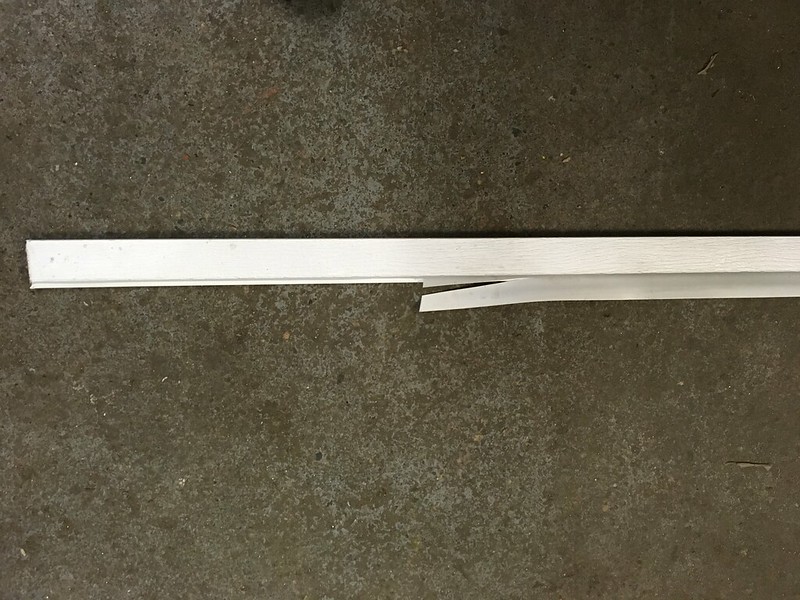

We have had an interesting time trying to get all this kit to work. Firstly the delrin bushings are wider than the sleeve that goes through them. This sleeve needs to end up slightly proud of the bushings so that it get clamped in the mounting slots and does not move. Then the bushings can rotate on the sleeve. Fortunately the sleeves appear to be the correct length.

It’s a good thing the bushings are also too thick as we need to remove some material to make them shorter than the sleeves. However, the sleeves are too tight in the bushings so we will also need to relieve them a little so they will actually rotate.

The top mounts don’t work either. Early on we had some spacers made to locate the upper spring perch and get some articulation in the mount but we won’t know how much articulation we need until we can mock-up a front and rear strut and control arm, but it’s definitely going to require more than we have now.

Unfortunately, due to the amount of hardware we are introducing to allow articulation we are also using up all of the threaded portion of the strut shaft and, although we can get a nut on we can’t access the hole in the top which will allow us to stop the shaft turning so we can torque it down.

To make things more interesting we have not yet found any off the shelf tubing of the correct dimensions to use as spacers so it will all have to be made.

The tops of the struts are also unfinished. We are concerned that these may corrode, especially the threaded sleeves. We are hoping our plating shop can zinc dichromate just the top portion as paint would be too thick.

And we thought not having to stick to OE parts would make this project fun!

On a brighter note we did have some small victories with the dash. We found and mounted a VW Beetle headlight switch:

And the period correct heated rear window switch:

Next update should include how we solve all the suspension issues, hopefully.

As you may recall the car came with some suspension parts, the origin of which we could not determine. Namely: delrin control arm bushings, coil-over conversion kit and spherical bearing top mounts.

We have had an interesting time trying to get all this kit to work. Firstly the delrin bushings are wider than the sleeve that goes through them. This sleeve needs to end up slightly proud of the bushings so that it get clamped in the mounting slots and does not move. Then the bushings can rotate on the sleeve. Fortunately the sleeves appear to be the correct length.

It’s a good thing the bushings are also too thick as we need to remove some material to make them shorter than the sleeves. However, the sleeves are too tight in the bushings so we will also need to relieve them a little so they will actually rotate.

The top mounts don’t work either. Early on we had some spacers made to locate the upper spring perch and get some articulation in the mount but we won’t know how much articulation we need until we can mock-up a front and rear strut and control arm, but it’s definitely going to require more than we have now.

Unfortunately, due to the amount of hardware we are introducing to allow articulation we are also using up all of the threaded portion of the strut shaft and, although we can get a nut on we can’t access the hole in the top which will allow us to stop the shaft turning so we can torque it down.

To make things more interesting we have not yet found any off the shelf tubing of the correct dimensions to use as spacers so it will all have to be made.

The tops of the struts are also unfinished. We are concerned that these may corrode, especially the threaded sleeves. We are hoping our plating shop can zinc dichromate just the top portion as paint would be too thick.

And we thought not having to stick to OE parts would make this project fun!

On a brighter note we did have some small victories with the dash. We found and mounted a VW Beetle headlight switch:

And the period correct heated rear window switch:

Next update should include how we solve all the suspension issues, hopefully.

#40

AudiWorld Member

Thread Starter

Like the suave, sophisticated gentleman in this video says “The car has legs now”

How did we get to this point? Well, as we discussed in our last post the delrin bushings are wider than the sleeve that goes through them. This sleeve needs to end up slightly proud of the bushings so that it gets clamped in the mounting slots on the subframe and does not move. Then the bushings can rotate on the sleeves. Fortunately the sleeves appear to be the correct length but they were also too tight in the bushings so we relieved them a little:

The bushings are also too thick so we removed some material to make them shorter than the sleeves and also added a chamfer so they would fit in the subframe slots:

Then we had to scour the globe to find ball joints:

Our top mounts that came with the car are held in place by four set screws so we had to get the drill out again:

We were worried that our bearing, spacer and nut combination wouldn’t have enough articulation so we assembled a front strut and put it through its entire range to see if it would be enough. It was, thankfully:

To celebrate this small milestone we threw on a wheel off our 85.

Maybe next update we’ll have figured the actual wheels and tires we will use. Maybe you can help by suggesting a wheel from the BRAID range. https://braidusa.com/collections/wheels

How did we get to this point? Well, as we discussed in our last post the delrin bushings are wider than the sleeve that goes through them. This sleeve needs to end up slightly proud of the bushings so that it gets clamped in the mounting slots on the subframe and does not move. Then the bushings can rotate on the sleeves. Fortunately the sleeves appear to be the correct length but they were also too tight in the bushings so we relieved them a little:

The bushings are also too thick so we removed some material to make them shorter than the sleeves and also added a chamfer so they would fit in the subframe slots:

Then we had to scour the globe to find ball joints:

Our top mounts that came with the car are held in place by four set screws so we had to get the drill out again:

We were worried that our bearing, spacer and nut combination wouldn’t have enough articulation so we assembled a front strut and put it through its entire range to see if it would be enough. It was, thankfully:

To celebrate this small milestone we threw on a wheel off our 85.

Maybe next update we’ll have figured the actual wheels and tires we will use. Maybe you can help by suggesting a wheel from the BRAID range. https://braidusa.com/collections/wheels

Last edited by team illuminata; 10-08-2018 at 07:20 AM.