Audi A3: Performance Diagnostic Guide

If your Audi A3's engine isn't performing as well as it normally does, that means something went wrong. Read on to learn how to diagnose the issue.

This article applies to the Audi A3 (2002-2008).

The Audi A3's engine should perform as well as it did when it was new. Any change of engine performance means one of a few components need to be replaced. Most of the parts that are responsible for engine performance have intervals in which they get replaced on. This guide will go over the common parts that could affect your engine performance. If you feel like your car isn't accelerating as well as it always has, then read on to learn how you can diagnose this problem.

Materials Needed

- Socket

- Pliers

- Long Phillips screwdriver

Step 1 – Check air filter

It could be dirty and clogged.

The air filter is the gate between the air outside of your engine compartment and your engine. It is designed to filter the air going into your engine. Over time, the filter gets dirty, which restricts the air going into your engine, thus decreasing its performance. To check and replace the air filter, you will need to remove the top of the air box. You can do so by removing the eight screws holding the top of the air box to the bottom, then disconnect the intake tube from the extension part, and pull them apart. The filter sits right under there. The air filter should be replaced every 50,000 miles, or bi-annually.

If the air filter is clean, proceed to Step 2.

Step 2 – Check spark plugs

They could be burnt.

The spark plugs are what give spark to your engine, so the weaker they get, the less spark your engine gets. The spark plugs should be replaced every 50,000 miles. Before inspecting the spark plugs, it's a good idea to check the spark plug wires. Any wears or cracks in them will directly affect the spark plugs, which will affect the engine's performance. The spark plugs are located under the coil packs. You need a deep socket to remove them. Inspect each spark plug's tip; if it looks burnt, replace all the plugs as a set.

If the spark plugs are in good shape, proceed to Step 3.

Step 3 – Check fuel injectors

They could be clogged or faulty.

The fuel injectors are designed to squirt just the right amount of fuel into the engine to assist in the combustion process. If one or more of these injectors fail, the engine won't get the amount of fuel it desires, which will cause it to run at a much lower performance. Remove the fuel rails to get to the fuel injectors, then inspect the injectors' tips. If they are dirty, clean them well so they squirt the correct amount of fuel. To check if they are working properly, use your long screwdriver with the engine on, and put it on the top of each injector. Place your ear on the other side of the injector and listen for a buzzing noise. If you hear a buzzing sound, that means your injector is working properly; if you don't hear anything, then you need to replace your injectors.

Step 4 – Boost leaks

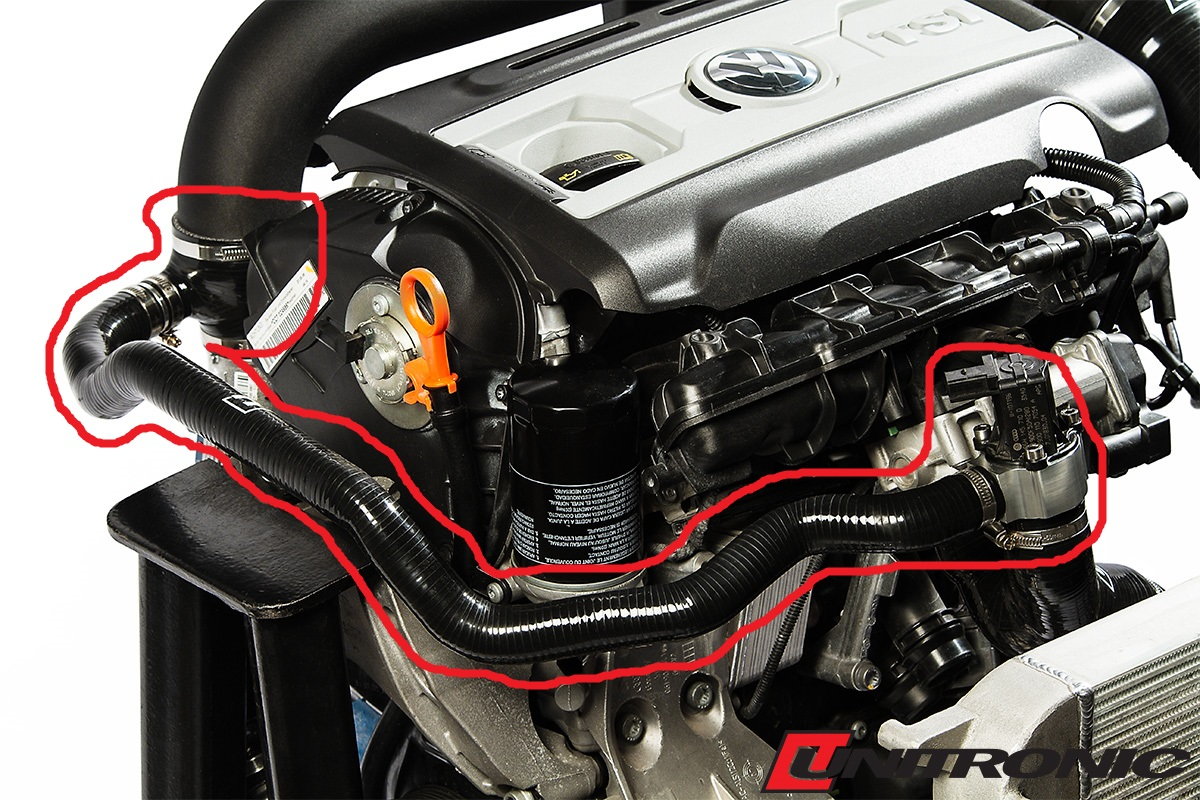

Having turbocharged engine is great! The boost comes on quickly and provides ample torque as well as power. However, a boost leak will reduce boost pressure being fed to the engine, and heavily compromise power and performance. The 2.0 TFSI engine is quite stout, but if there is one common weak link, it is the diverter valve.

The diverter valve is located on the turbo charge pipe, which is the pipe that goes from the intercooler to the throttle body. The diverter valve uses a plastic diaphragm to divert excess boost pressure when you left off the throttle by recirculating that excess boost back into the intake tract. The stock diverter valve's plastic diaphragm and its seal can become compromised with age or increased boost and will no longer provide a good seal. This means that boost pressure is bled out when it's not supposed to, which means that boost is not reaching the engine. Aftermarket diverter valves use metal diaphragms that do not leak.

To test the diverter valve, remove it from the charge pipe, and using an air compressor or tire inflator, run air through it to test the action of the diaphragm. With the vacuum line uncapped, air should pass through the tubing. Now plug the vacuum line, or use vacuum pump on the vacuum line and run air through the valve. If air is still passing through the valve, even if it's a little bit, the diaphragm is leaking and requires replacement.

Related Discussions

- Loss of Power - AudiWorld.com

- Rough Idle - AudiWorld.com

- Sudden Power Loss - AudiWorld.com